Agents & Distributors

We are looking for you

For the German and worldwide distribution of our innovative products. WiMedical develops and produces solutions for the protection of surgical instruments. Our top priority is to improve surgical outcomes, increase long-term savings and improve patient safety. To ensure the highest level of quality, we rely on competent partners and advanced manufacturing standards.

Our company headquarter is in Singen, Germany. We are thus close to the “World Center of Medical Technology Tuttlingen” and can build on a strong network of partners and suppliers. To be able to offer our customers a high level of quality and delivery reliability, we develop and manufacture our products “Made in Germany”.

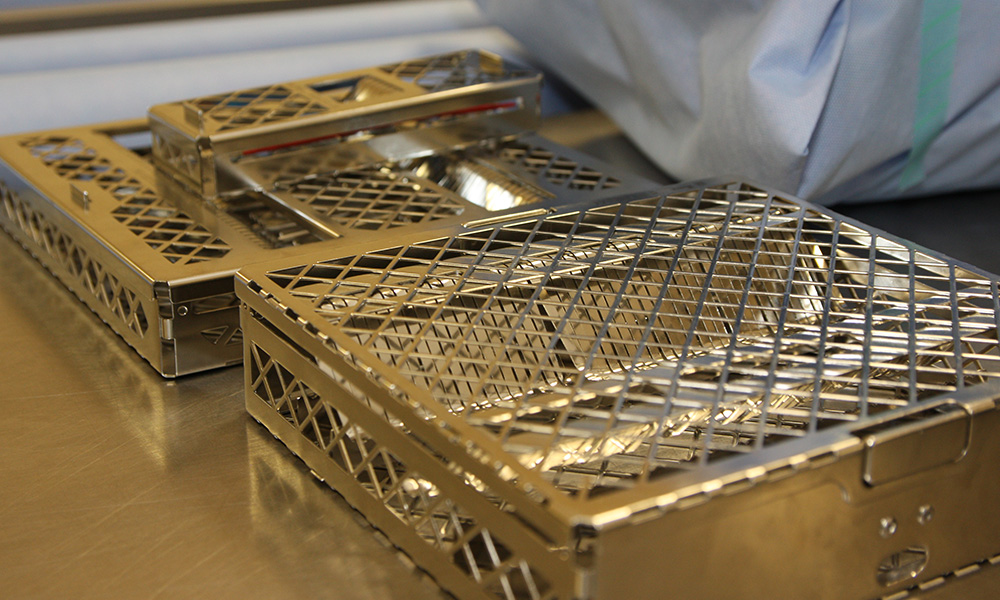

With our self-developed, award-winning and patented MUNDITIA SYSTEM CASE we protect and organize sensitive surgical instruments and medical devices during sterilization, transport and storage.

As a sales representative and distributor,you can offer your customers a wide range of benefits with our Munditia System Case:

Improves the quality

The preparation, as the rinsing shadows are reduced to a minimum (approx. 1 mm per contact point).

Saves costs

By protecting your sensitive and expensive medical instruments with secure fixation. You also save running costs for the purchase of additional plastic holders in the tray.

Environmental protection

While you store your instruments on plastic materials (mats, clamps, containers), the Munditia System Case completely dispenses with plastic and at the same time improves the fixation of the instruments in the container.

Process Improvement

During the cleaning process by easy and flexible loading and fixing of your medical devices.

Your profile

You have already been working in direct sales for several years and can demonstrate success in this field. Ideally, you are already active in medical device sales and have already sold new products in the medical industry. You are characterised by enthusiasm and ambition and are used to working independently and on your own responsibility. In the best case, you or your sales organisation already have access to CSSDs / AEMPs in clinics and MVZs or practices.

Within your sales area you will acquire and support clinics, practices, MVZs and medical device manufacturers in the B2B sector. Within Germany, sales representative areas are assigned. Worldwide country territories are assigned to distributors.

Our services in detail

As a sales representative and distributor, you will receive a broad portfolio of innovative products from us. You benefit from our Munditia System Case series both as product catalogues and from our custom-made products which you can offer to your customers. Furthermore you have the possibility to receive commissions on development and prototyping, sheet metal and tube processing, workpiece carriers and magazines, contract manufacturer for medical instruments and hygiene products.

Our offer

- intensive training and familiarisation

- complete internal sales support for the preparation of offers and order processing

- technical and medical support for development requests

- Commission-based remuneration

- Patented and protected products

- a dynamic company with a proven high degree of innovation

- “Door opener products” that convince through their high innovative power

Services for trade representatives & distributors

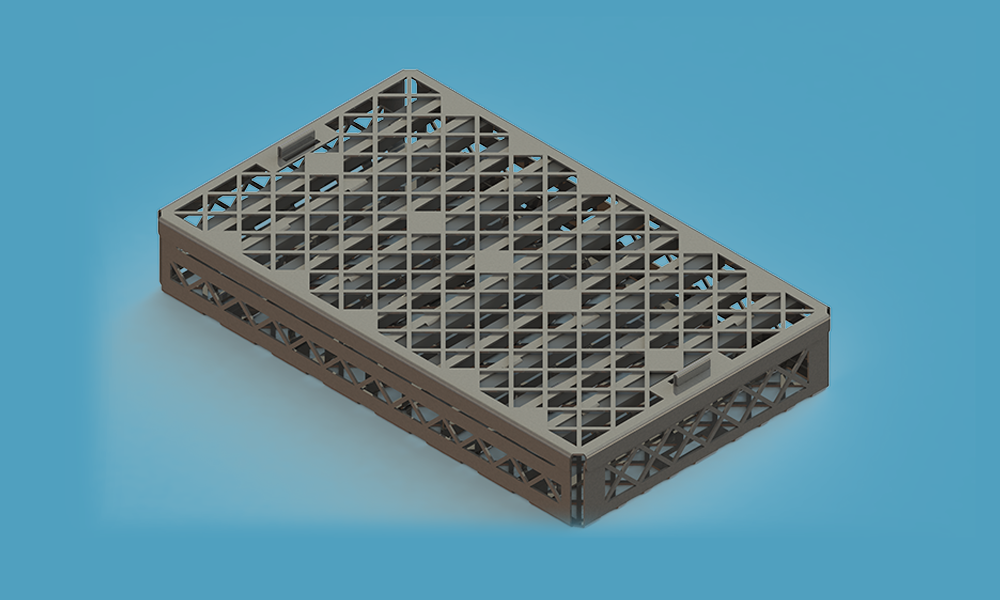

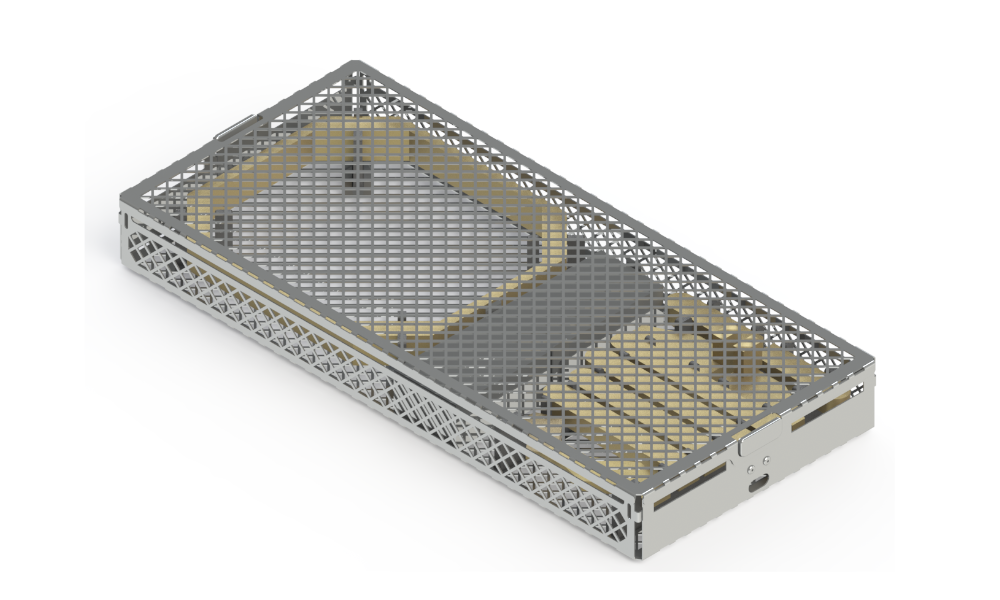

Munditia System Case catalogue products

You will receive a wide selection of sterilization trays and accessories for all challenges in the reprocessing of your medical instruments. Our catalogue offer for you consists of five product categories:

- Munditia System Case Flex Smart

- Munditia System Case Flex Hybrid

- Munditia System Case Standard

- Munditia System Case Special

- Munditia System Case Zubehör

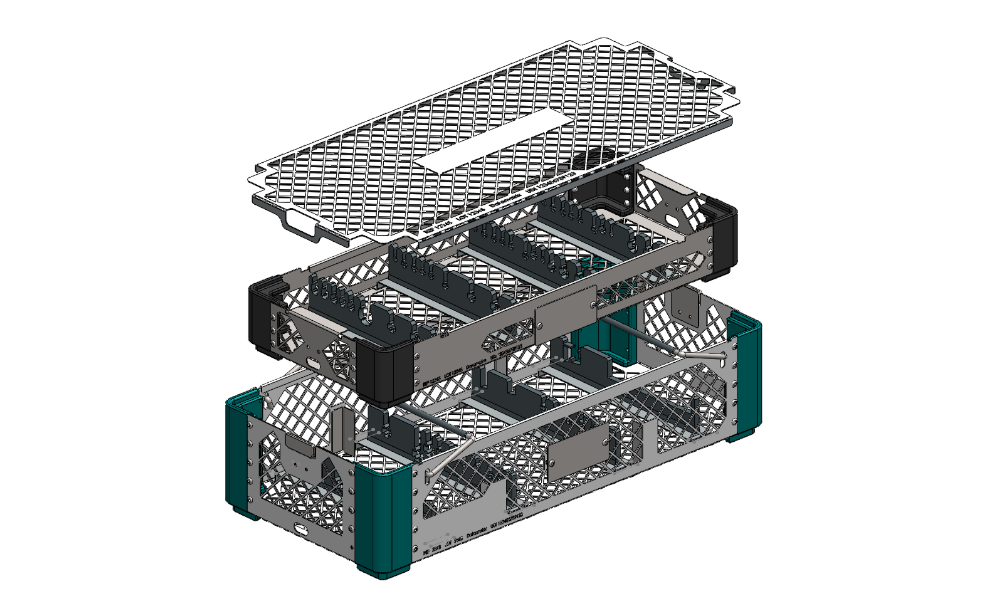

Munditia System Case custom made

With our Munditia system cases we configure the right system tray for your instrument set. The custom-made products are designed according to the customer’s wishes and adapted to the respective medical products. In this case, a label can also be generated for the loading in the set to provide a visual loading aid. We accompany you during the entire process:

- Project planning and consulting

- Development

- Set composition according to your specifications

- Set labeling

- Series production

Workpiece carriers and magazines

With our carrier systems, you receive solutions that help you to realize even more efficient and safe processes. We guarantee a secure hold and a minimum contact surface between holder and product. Easy removal for robot production centres ensures a precise delivery date and process reliability. All hole patterns, partial holders and fixings are adapted to your products and precisely adapted.

We use different stainless steels, aluminium and plastic inserts with different surfaces for our carrier systems and magazines. Our quality guarantees a high degree of accuracy and durability. Transport your parts inside and outside your company with our workpiece carriers and magazines.

Development and prototyping

With us you get a partner who has a modern 3D design program, which makes us the ideal partner for our customers for production and development. New products or product optimizations are daily business for us and our systems. The first prototypes can be realized at low cost with a 3D printer if desired. Together with you, we design the step towards “Industry 4.0”! With our 3D CAD program all assemblies are individually displayed. On the basis of the 3D data created, extensive calculations such as surface determinations, breaking tests, strength calculations and a photorealistic representation can be generated.

Sheet metal and pipe processing

Sheet metal processing using the latest manufacturing technologies ensures products of the highest quality and process reliability. Our range of services in the field of sheet metal processing includes the development, design and manufacture of technical sheet metal parts and complex sheet metal assemblies made of thin sheet metal in samples, small and large series.

Fast order processing and tailor-made manufacturing concepts make us a recognised contract manufacturer in the sheet metal working industry for sheet metal components with the highest level of quality. Constant quality controls ensure products of first-class quality.

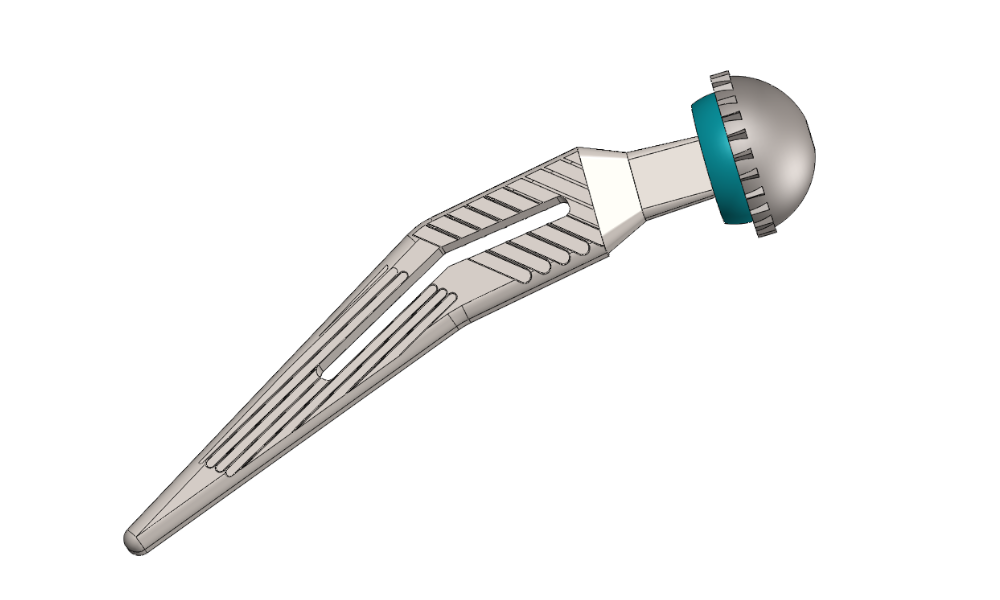

Contract manufacturer for medical instruments

As an innovative company, we develop and manufacture high-precision components for you from various materials, especially stainless steel or titanium. Our previous projects include screwdriver blades, surgical instruments in the orthopaedic and spine sector as well as various sheet metal components for medical technology. Thanks to our extensive network, we can handle projects quickly, efficiently and with high quality.

As your partner, we accompany you from development, prototyping and production, labeling, packaging and logistics.

Hygiene products

Use our hygiene products such as 3-layer surgical masks, mouth and nose masks or disinfection stands to protect yourself and your employees from Covid19.

WiMedical stands for innovative and excellent products.

Innovations are and will remain the key to success. That is what we believe in. We have already received several awards for this. Our awards and nominations include

- 2019 German Medical Award – Category Company – Innovative Product – Nomination

- 2019 1st place founder price Schwäbisch Media

- 2018 1st place start-up bw Elevator-Pitch Weingarten

WiMedical stands for„Made in Germany“.

This means that you receive sustainable and high-quality solutions from us. All products are developed and produced in Germany. Due to our company headquarter in Singen we are very close to the world centre of medical technology in Tuttlingen and can rely on a functioning network of partners and suppliers.

WiMedical stands forquality.

We manufacture according to ISO 13485, the standard especially for the medical technology industry. Our quality management system (QMS) meets the requirements of the 93/42/EEC directive. WiMedical focuses on the safety of its products and the fulfilment of legal requirements.

WiMedical stands forsatisfied customers and partners.

WiMedical stands forvalues.

Innovation

By this we mean being open to new things. We develop innovative and creative solutions together with our customers. We are prepared to take calculable risks. The reason for this is to improve ourselves and to satisfy our customers quickly and precisely.

Efficiency

All our solutions are developed very efficiently for our customers. This means that the effort for handling our solutions is as low as possible. The benefit is high.

Sustainability

By sustainability we understand to develop systems for our customers which contain as low follow-up costs as possible.

Get in contact with us

If you have any questions about our offers, would like a consultation or would like to find out more about our services, please send us your inquiry via our contact form or give us a call.